Micro Perforated Panels | micro perforated acoustic panels

Micro-perforated acoustic panels, also known as micro-perforated panels (MPPs), are advanced sound absorption solutions designed to control noise and improve sound quality in different environments. These panels consist of a composite material with tiny perforations or holes that allow sound waves to pass through. The sound waves then enter the panel, where they get trapped and dissipated, reducing the overall echo and reverb effects.

At Packsound, We manufacture and offer Ultra Micro Perforated Panels processed with Wood and Metal considered best for wall acoustic globally. Ultra Micro-perforated panels have regular very thin holes enabling them to be a quality acoustic product. Micro-perforated MDF board not only has a good sound-absorbing effect but also looks great visually. Compared to bigger holes wooden perforated panel, the ultra micro hole acoustic panel is harder to make and is better at absorbing low frequencies of sound.

The surface of the panel is drilled with numerous tiny micro perforations which can provide excellent acoustical performance. The panels are designed to trap the noise and reduce the reverberation time in the room. With 0.5 mm micro-perforation, the perforation is practically not visible, keeping the finish completed. The hole dimensions can be 8-8-0.5 mm according to different types, the distance and distribution of the holes will be different, and each square meter can approximately have 140,000 holes.

Features :-

Our Micro Perforated Panels Have

- Approx. 50 color available.

- Core Variants – MDF, Ply, Fire Rated Ply, WPC Board

- Enhanced Sound Quality

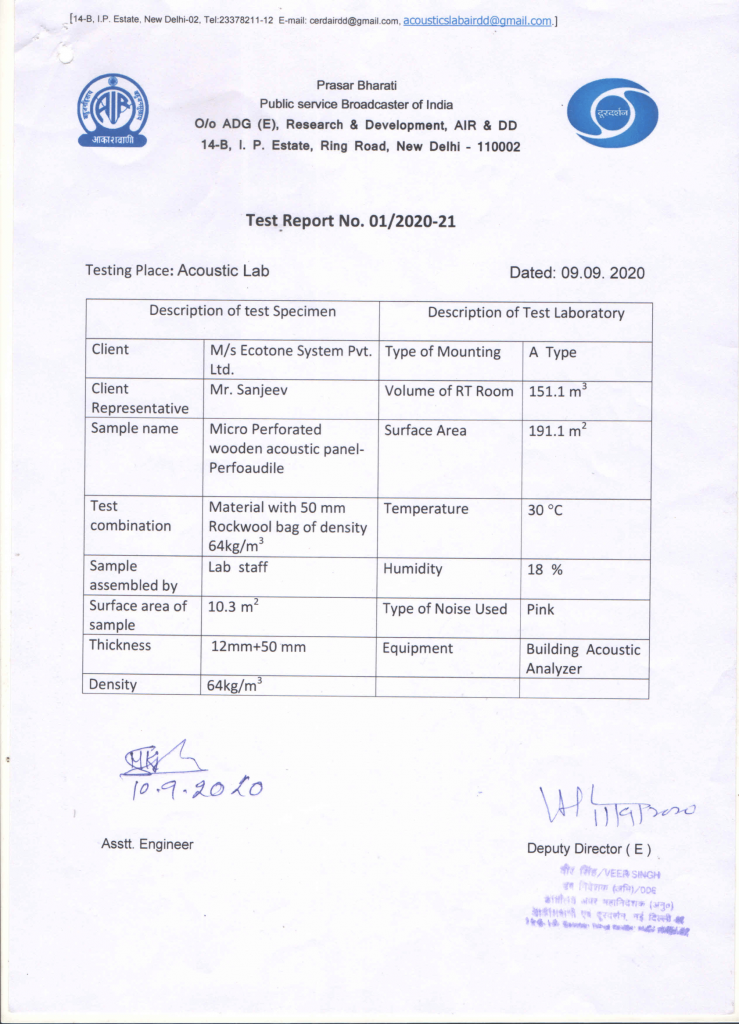

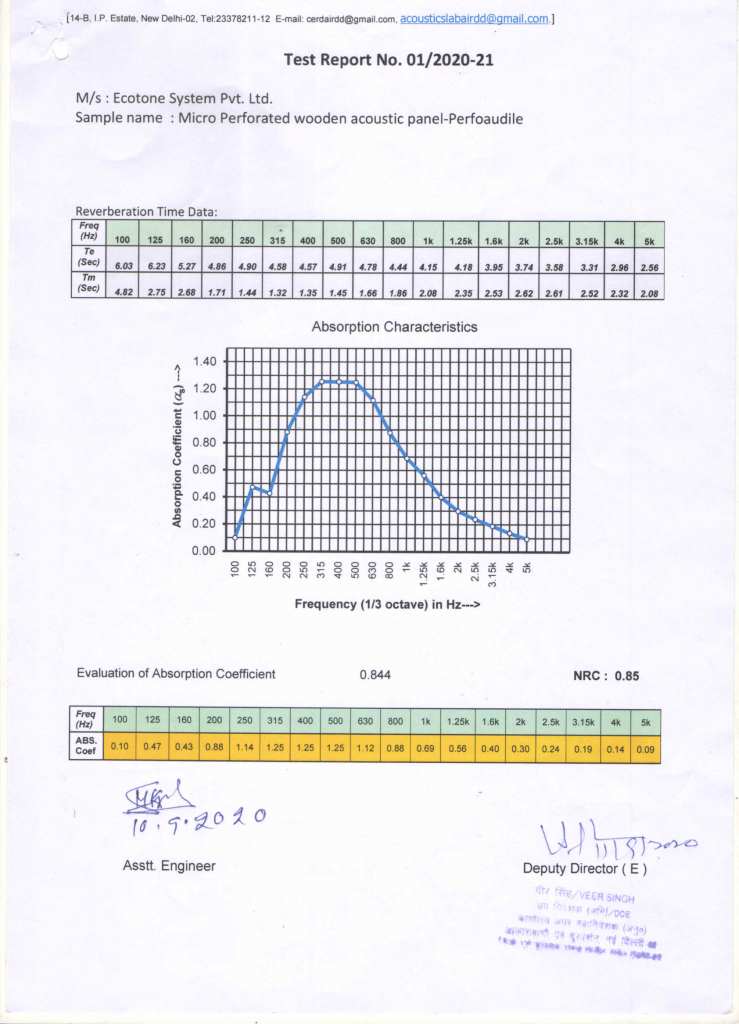

Technical Information Of Micro Perforated Acoustic Panels

FAQs| Micro Perforated Panels

What are the primary factors to consider when selecting Micro Perforated Panels?

A. When choosing Micro Perforated Panels, it’s important to consider factors such as the desired acoustic performance, the size of the space, the aesthetics of the panels, and the installation requirements. Consulting with an acoustic professional or supplier can help ensure the right panel selection for your specific needs.

Can Micro Perforated Panels be used in outdoor applications?

A.Yes, Micro Perforated Panels can be used in outdoor applications, provided they are designed and manufactured for outdoor use. Outdoor Micro Perforated Panels are typically constructed using materials that are resistant to weather conditions, such as aluminum or composite panels with suitable coatings.

Can Micro Perforated Panels be customized to match specific design requirements?

A.Absolutely! Micro Perforated Panels offer customization options in terms of finishes, colors, patterns, and sizes. They can be tailored to align with the design vision and aesthetic requirements of a project, ensuring a harmonious integration with the overall space.

[wpforms id=”7352″]